In an effort to deliver safe, high quality products to our customers, Mishima Foods maintains and promotes solid production and hygiene management systems. In particular, we have built a system based on visual management*1-driven plant operation together with our unique production information system that includes HACCP and quality information, where quality is given shape through the production process.

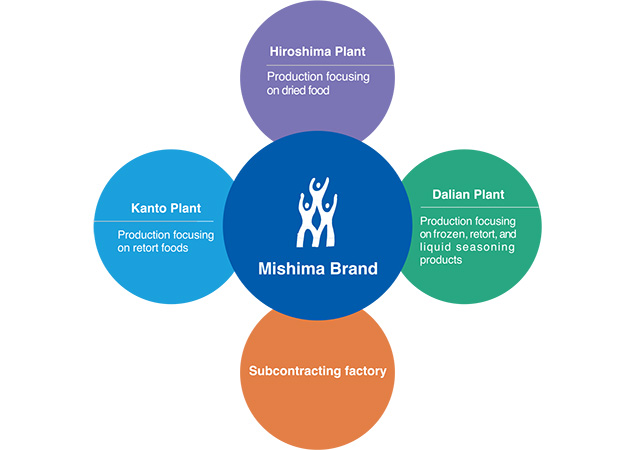

Focusing on dried food such as Furikake*2, seasonings, and cooking materials, we season and reprocess superior ingredients while giving due consideration to the natural color and flavor of each ingredient.

We produce retort foods by sealing food completely in pouches made of synthetic resin film and aluminum foil or in molded containers, sterilizing them with heat and high pressure (retort sterilization)*3.

In an effort to make the most of the flavor and taste of fresh ingredients in China, we established our plant in Dalian, a city close to a raw material production area, where we mainly produce retort foods.

*1 Visual management: an effort in management to share information within an organization to detect problems early on and streamline and improve operations in plants.

*2 Furikake: Traditional Japanese multi-purpose seasoning

*3 Retort foods: Foods that are sealed in airtight and lightproof containers and sterilized by heat and pressure.